- Ceramics Industry

- CUBA: LEGISLATIVE CHANGES AFFECTING CONSTRUCTION

|

|

|

|

|

|

From November 10, for the first time in more than 50 years, Cuba will allow the sale, exchange, donation and allocation of private homes. The measure, which aims to "eliminate prohibitions", will allow each resident to own two homes, one used as a normal place of residence and another as a holiday home.

The decision is part of a set of economic adjustments to "update" the socialist model of the island's president, Raúl Castro, in his desire to eliminate "prohibitions". The different options for the transfer of property are to be made before a public notary and will be subject to the payment of a tax which has not yet been clarified.

For the first time in more than half a century citizens will be able to buy and sell homes legally, without resorting to the black market. Last month the Cuban government authorized the sale of vehicles for its residents and is expected to soon make emigration from the island more flexible.

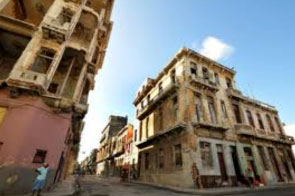

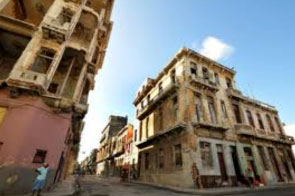

With 11.2 million people, Cuba, up until 2010, had a recognized deficit of about 600,000 homes, in part due to three hurricanes that caused damage in 2008, though according to official figures more than 50% of the buildings on the island are in poor condition and about 8.5 out of 10 buildings are in need of repair, in addition to unfulfilled government construction plans.

BERALMAR has experience in the Cuban market, having supplied engineering projects and equipment to a total of eight ceramic plants.

|