|

|

| Newsletter 90 - February 2015 |

| Approximate reading time: 5 minutes |

|

|

|

|

- Corporate

-

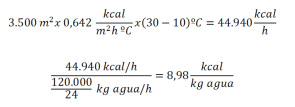

SEVENTEENTH PART OF THE TREATISE ON DRYING AND FIRING

In this seventeenth instalment, you will find chapter 1.13 of the treatise on drying:

Chapter 1.13: Heat balance in a dryer.

We hope it will be of interest to our readers.

|

|

|

|

|

|

-

CONCLUSIONS FROM THE “SIBBUILD 2015” FAIR

Between 3 and 6 February, BERALMAR took part in the SIBBUILD Fair in Novosibirsk (Siberia, Russia) for the first time.

This first experience of the SIBBUILD fair was very positive given the circumstances, as in spite of current geopolitical uncertainties and the recent significant falls in the value of the ruble, the number of visits attended to on our stand and the conversations held showed there are needs and enthusiasm for undertaking projects in the region.

It should be remembered that BERALMAR supplied and commissioned a complete factory in Siberia in 2014, specifically in Kansk, near Krasnoyarsk. This is, then, a region where BERALMAR is well aware of the technical and energy requirements.

|

|

|

|

|

|

-

BERALMAR AT THE “KYIVBUILD 2015” FAIR

As has been the norm for many years now, BERALMAR will again attend the KYIVBUILD fair, to be held between 3 and 5 March in the Ukrainian capital.

Friends and clients can meet the people from BERALMAR on stand number G4-1 in the Kiev International Exhibition Centre.

Fuels are currently seeing wide variations in prices in the Ukraine. This means it is essential to pay close attention to energy costs. In this context, Ukrainian manufacturers can find many solutions in BERALMAR. We hope this edition of KYIVBUILD will be a good chance to comment on these.

We look forward to seeing you there!

|

|

|

|

|

|

-

BERALMAR AT THE “MOSBUILD 2015” FAIR

BERALMAR returns to Russia to exhibit for the third time in 2015, this time in the MOSBUILD fair, to be held between 31 March and 3 April.

BERALMAR’s visitors will find us on stand L-153 in Hall 2, Pavilion 5.

BERALMAR’s intensive participation in trade fairs in Russia is explained by our conviction that the current situation, characterized by a highly devalued ruble, is temporary. We believe, then, that this participation will be of interest to all.

|

|

|

|

|

|

-

BERALMAR AT THE BIG 5 SAUDI 2015 FAIR

BERALMAR will take part, for the first time, in THE BIG 5 SAUDI fair, to be held between 9 and 12 March in Jeddah (Saudi Arabia).

Visitors can meet the people from BERALMAR on stand 2A-23 of the Jeddah Centre for Forums & Events.

The city of Jeddah, on the Red Sea coast, was the center of a great deal of media attention a few years ago when the construction of the world’s tallest skyscraper, the Kingdom Tower, was announced. Works for this ambitious project started in April 2013 and when it is completed, in 2019, the building will have 167 floors and be 1 mile (1.6 kilometres) high.

|

|

|

|

|

|

- News and Accomplishments

-

NEW MAXIMUM ENERGY EFFICIENCY PROJECT IN MOROCCO

|

|

|

| Cars stacked with green and fired products, in a BERALMAR factory with similar characteristics.

|

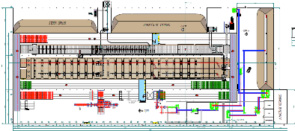

BERALMAR is already working on a new project. This is the supply of a new factory, the new AMINA BRIQUES plant, being built halfway between Tangiers and Tétouan, one of the regions of greatest economic growth in Morocco.

The project is of significant dimensions, as the new production line will have a production capacity of 800 tonnes/day of various ceramic block formats

BERALMAR’s supply for the AMINA BRIQUES project comprises:

- Complete cutting line

- Direct setting of wet material onto kiln cars

- LLEVANT model kiln car dryer, with two 183-metre tunnels

- PRESTHERMIC model high-performance airtight tunnel kiln, 183 metres in length

- Kiln car dehacking

- Package formation using plastic wrapping

It is worth pointing out that it was possible to plan this production line thanks to the characteristics of the clay available and the industrial testing carried out, providing the project with full technical guarantees. It is also due to BERALMAR’s versatility, with its experience in constructing all kinds of dryers. This means it is capable of adapting to each context with the most technically suitable proposal, with no self-imposed limits.

If this project features one aspect, it is undoubtedly energy efficiency; the owner’s great – and highly recommendable – obsession, which found an ideal partner in BERALMAR. On the one hand, direct drying on kiln cars and the efficiency of the airtight kiln mean that a maximum specific consumption of only 323 kcal/kg is anticipated for drying and firing. On the other hand, added to this low consumption is the use of low-cost fuels. The dryer will mainly be fed with heat recovered from the kiln, with intermittent contributions from a biomass (specifically olive pomace) heat exchanger. Meanwhile, the tunnel kiln will have a BIOMATIC firing facility. This permits alternating or simultaneous consumption of biomass or micronized petcoke fuels, both of which are available at a good price in Morocco. The criterion on defining each point in the project, then, was to opt at all times for those alternatives which enabled the energy costs in this new factory to be reduced to a minimum.

We would like to record our thanks here to the owner and management of AMINA BRIQUES for the trust placed in BERALMAR, with the full conviction that the result will be among the most competitive production lines.

|

|

|

|

|

|

www.beralmar.com | Change language | Unsubscribe | Disclaimer

Beralmar Tecnologic, S.A. | Avda. del Vallès, 304 | E-08227 Terrassa (Barcelona) | T. +34 937 312 200 | info@beralmar.com

|