|

|

| Newsletter 85 - September 2014 |

| Approximate reading time: 5 minutes |

|

|

|

|

- Corporate

-

HISTORY OF BERALMAR, 7/10: 2003-2009 – CONSOLIDATING AROUND ENGINEERING AND SOLID FUELS

|

|

This period does not stand out for any remarkable organisational leap forward, but rather for steady growth based on consolidation and exploitation of the groundwork that had been previously laid.

On the one hand, the Engineering Department business was considerable. In only 6 years, the company sold about 20 tunnel kilns and 20 dryers of various types in Spain, Algeria, Hungary, Cuba, Canada, Morocco and Argentina.

During the same period, the company witnessed growing demand for solid-fuel firing equipment in many markets, especially Spain, the Balkans and the United States. BERALMAR, which has been a leader in this type of technology for years thanks to its experience accrued with the PROMATIC system, in 2002 had barely began to develop and commission its first MICROMATIC installations for using micronized petcoke. BERLAMAR thus found itself in a privileged position to take the lion’s share of the market. In only six years it received orders for PROMATIC and MICROMATIC installations for about 70 tunnel kilns, at the rate of about one commissioning per month.

As a result of this sales success, BERALMAR doubled turnover in a matter of 6 years.

In this period, the company had 45 employees, in addition to a growing number of external commercial agents.

|

|

|

|

|

|

-

TWELFTH PART OF THE TREATISE ON DRYING AND FIRING

In this twelfth part, you will find chapter 2.8 of the treatise on firing:

Chapter 2.8: Types of burners.

2.8.1: Micronized-coke installations.

We hope it will be of interest to our readers.

|

|

|

|

|

|

-

CONCLUSIONS FROM THE TECNARGILLA FAIR 2014

In late September BERALMAR participated in the TECNARGILLA 2014 fair held in Rimini (Italy).

BERALMAR’S specific take-aways from this TECNARGILLA edition are bittersweet:

- On the one hand, we greatly appreciate and value each and every visit received at our booth, which has allowed us exchange information, concerns and needs with a number of ceramists from some 20 countries.

- But at the same time, the decline of the CLAYTECH space in this fair (the structural ceramics pavilion) is obvious. The number of exhibitors and visitors has dropped substantially with every edition, to the point that the exhibitors this year only took up half the pavilion.

The organizers would do well to reflect on possible causes behind this progressive and marked decline in exhibitors and visitors. Given that the decline began in 2008, when the fair switched from a triennial to a biennial calendar, we cannot help but think that this is one of the main reasons.

In any case, we encourage fair organizers to identify the causes behind the decline of the CLAYTECH space and so, to everyone’s benefit, restore what had been the world's leading fair in our industry, together with the CERAMITEC fair in Munich (Germany).

|

|

|

|

|

|

-

BERALMAR AT THE KIEV CONFERENCE ON "ENERGY EFFICIENCY IN INDUSTRY AND AGRICULTURAL-INDUSTRIAL COMPLEX"

|

Oleg Polchiy during his presentation Oleg Polchiy during his presentation |

The I International Conference on "Energy Efficiency in Industry and Agricultural-Industrial Complex” took place in Kiev (Ukraine) on 4 and 5 September, featuring the participation of 44 speakers addressing nine thematic areas.

BERALMAR took part at this event with a presentation by Oleg Polchiy and Santi Amposta called "Efficient equipment for solid fuel consumption instead of gas, for agriculture and the production of building materials”.

|

|

|

|

|

|

-

VISIT FROM THE ASSOCIATION OF POLISH CERAMISTS

On 29 September we had the pleasure of receiving a delegation from the Polish Ceramist Association at our BERALMAR facility in Terrassa.

The visit served, among other things, for some members of the delegation who had already visited our company a few years ago to see first hand the changes in our organization since their last visit.

We hope that this tour proved interesting and enjoyable for them, and — as we always say — that our visitors left with the feeling that BERALMAR is their home.

|

|

|

|

|

|

- News and Accomplishments

-

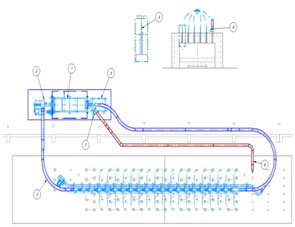

NEW MICROMATIC INSTALLATION IN MOROCCO

In Morocco, the conversion from fuel oil to micronized petroleum coke as a reference fuel continues to advance. There are few tunnel kilns that do not yet use this solid fuel in the North African country.

BRIQUETERIE SIDI KACEM in the city of the same name has again turned to BERALMAR for the installation of a new MICROMATIC system for the Unit I kiln, producing about 300 tons/day of ceramic blocks. A few months ago, Beralmar installed a MICROMATIC system for the large kiln at BRIQUETERIE SIDI KACEM. Upon seeing the good results, the ceramic plant’s management decided to adopt the same solution for the factory’s small kiln.

This is BERALMAR’s 17th solid-fuel firing installation in Morocco in recent years.

We want to thank BRIQUETERIE SIDI KACEM management for their continued confidence in BERALMAR.

|

|

|

|

|

|

|

www.beralmar.com | Change language | Unsubscribe | Disclaimer

Beralmar Tecnologic, S.A. | Avda. del Vallès, 304 | E-08227 Terrassa (Barcelona) | T. +34 937 312 200 | info@beralmar.com

|

Oleg Polchiy during his presentation

Oleg Polchiy during his presentation