|

Approximate reading time: 5 minutes

Ceramic Industry

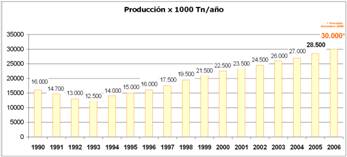

Spain, the largest ceramic material producer in europe

According to HISPALYT (the Spanish association of brick and roof tile manufacturers), by the end of 2006 Spanish brick makers will achieve an annual production of around 30 million tonnes of structural ceramic material, a figure higher than that of Italy, Germany or the United Kingdom.

Such output represents an increase of 7.5% over the previous year, which cannot be explained by just the strength of construction activity, but also by a solid tradition in the use of ceramic materials in construction. In the consolidation of this tradition, and in the success in competing with alternative construction materials, things are not left to fate: the active and coordinated behaviour of the ceramic industry is largely responsible, as exemplified once more by this year’s campaign to promote the use of ceramic materials using television and radio commercials.

BERALMAR TECNOLOGIC, through its own initiative, has contributed significantly and for a second time to the funding of this campaign, which under the motto “paredes de ladrillo, las de toda la vida” (roughly “good old-fashioned brick walls, ”) has based a message urging the end users to picture a world without bricks, while stressing the safety, comfort, resistance, fire protection and acoustic isolation provided by constructions with ceramic materials.

|

Corporate

Beralmar in central europe, in perspective

Up until the year 2000, BERALMAR had focused its commercial activities in Spain, the neighbouring markets (Portugal, France, Morocco, Algeria) and the Americas. That year, with the forecast of the promising growth of Central European economies and their construction activities, it was decided to broaden the geographical scope and to set foot in these markets. Hence, a slow process of mutual acquaintance between the region’s brick makers and BERALMAR started. The difficulties in those markets where other suppliers enjoy a longer presence were no surprise, but the conclusions today are positive, and the expectations, high.

Currently, BERALMAR employs its own staff in a large number of Central European markets, and with a growing reference list in the region, both in the supply of equipment and in engineering projects.

In this context, BERALMAR insists in its long term strategy, after overcoming the hardest phase of its introduction to the region, and now faces the challenge of becoming a major supplier in Central Europe. Constant technological innovation and competitive quality, price and service will be keys to the meeting of this challenge.

|

|

New facilities in beralmar

Due to a growing staff, BERALMAR has completed the construction of new facilities for the technical office at its headquarters in Terrassa (Barcelona), a much-needed response to the increasing demand for work space.

The new technical office incorporates the Projects Department directed by Artur Massaguer, the R+D Department managed by Santi Amposta and the Manufacturing Design headed by José Cabello.

The new facilities also include a new meeting room and a new archive.

|

Technological news and Performances

New dual injector for gas and solid fuels

In its constant investment in R+D, BERALMAR has developed a new dual injector making it possible to inject gas and solid fuels alternatively.

This injector is adaptable to BERALMAR’s groups of gas burners and to the distributors of the PROMATIC and MICROMATIC solid fuel firing systems.

With the current increase of solid fuels consumption in the ceramic industry, BERALMAR has developed this injector in order to facilitate the switch of fuel injected in the kiln, without the need to physically move any firing equipment on the kiln. The switching of fuel can be done from the kiln automatic control.

This injector has already been put into practice successfully in a kiln in the U.S.

|

|

The world’s best solid fuel firing system

This month BERALMAR started up the most outstanding solid fuel firing system in the world.

A few months ago, the SOCIÉTÉ BRIQUETERIE BATI CHAOUIA of Berrechid, Casablanca (Morocco), entrusted BERALMAR with the replacement of their fuel-oil firing systems in the plant’s 3 kilns with a petcoke firing system. The project consists of a central grinding mill of huge proportions, an intermediary silo to stock micronised fuel, and the subsequent feeding to 3 independent MICROMATIC systems, one for each kiln.

This fully automatic and centrally controlled installation supplies the 3 kilns with 70% of the energy required for a daily combined production of 1,500 tonnes of hollow brick.

Due to its cutting-edge technology, its fuel consumption efficiency, its firing quality, the dimensions of the project and the fully automated facility, BERALMAR considers the solid fuel firing system installed for S.B. BATI CHAOUIA the most remarkable in the world.

|

|

New project in venezuela

The firm ALFARERIA CABIMAS of Venezuela handed over the construction of a new tunnel kiln to BERALMAR, for the production of 75,000 roof tiles a day.

This new production facility, which will use natural gas as its main fuel, will be a PRESTHERMIC kiln, 125 metres long. The PRESTHERMIC kiln is conceived and designed to be a sophisticated installation offering top performance in the production of structural ceramics thanks to the materials used in its construction and sealing ability, enabling operation and high temperatures with no energy loss.

The project start-up is due in May 2007.

|

|

|