Новости

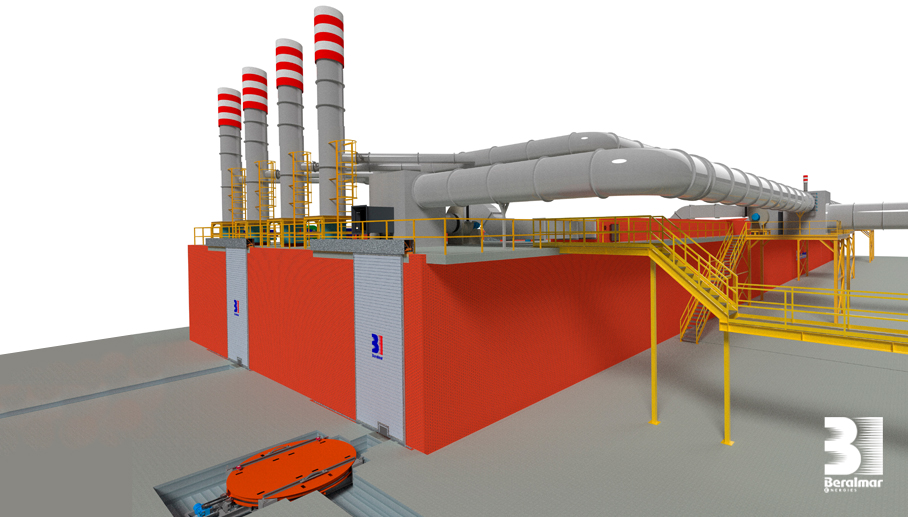

New Dryer Modernization Project in Europe (03.12.2025)

Beralmar Energies has been selected to modernize an existing dryer, with the goal of optimizing process control and improving the plant’s energy efficiency.

The project includes upgrades to the ventilation system that enhance heat recovery, allowing more efficient use of kiln energy and improving drying uniformity. An air flow measurement system will also be installed to accurately assess heat recovery towards the dryer, ensuring a proper thermal balance.

In addition, the incorporation of pre-chambers and new doors will reduce air and heat losses during operation, increasing the stability and performance of the dryer.

These improvements will enable a more efficient, controlled, and sustainable drying process, increasing the overall performance of the plant. With this project, Beralmar Energies reaffirms its commitment to innovation and excellence in the ceramic industry.

The project includes upgrades to the ventilation system that enhance heat recovery, allowing more efficient use of kiln energy and improving drying uniformity. An air flow measurement system will also be installed to accurately assess heat recovery towards the dryer, ensuring a proper thermal balance.

In addition, the incorporation of pre-chambers and new doors will reduce air and heat losses during operation, increasing the stability and performance of the dryer.

These improvements will enable a more efficient, controlled, and sustainable drying process, increasing the overall performance of the plant. With this project, Beralmar Energies reaffirms its commitment to innovation and excellence in the ceramic industry.