- Company

- Company background

Company background

Beralmar Tecnologic S.A. Commenced operations in Spain. Over time, the Company has entered the international market, and is now a major exporter able to service different markets.

Its headquarters are in Terrasa, a stone's throw from Barcelona. Its has a 7,500 m2 facility.

2014

2013

2012

2011

2010

2009

2006

2005

2004

2003

2002

2001

1998

1996

1993

1990

1989

1982

1976

1964

2014-50th anniversary

50 years have passed since the foundation of BERALMAR. Currently, it is the longest established engineering company in Spain. The anniversary comes at the right time for the company. We have customers in more than 50 countries and Beralmar's name and technology are recognised in the world of ceramics.

Throughout this period, the Company's technical team has evolved and grown to the point of boasting its very own high-level technology in order to take on a project for an entire plant of any product, not matter how complex it is.

BERALMAR is an entire plant supplier and a world leader in burning systems. It has the capability to provide the right solution for any kind of fuel, clay or ceramic blanking plates all around the world.

2013-Internationalisation Award

The Terrassa Chamber of Commerce presented Beralmar for the Internationalisation Award in recognition of the company’s export endeavours, whereby more than 90% of its turnover had been derived from exports.

This was the year for the supply of the first tunnel kiln to produce refractory materials, which operated at 1300°C and was commissioned by Refractarios Campo in Galicia.

2012-Exports reached record levels

As a result of a marketing strategy that had begun many years ago, more than 90 % of Beralmar's turnover had come from exports. The fall of internal demand was not the only explanation for this figure, as Beralmar had strengthened its active commercial presence in more than 50 markets to substitute the internal market.

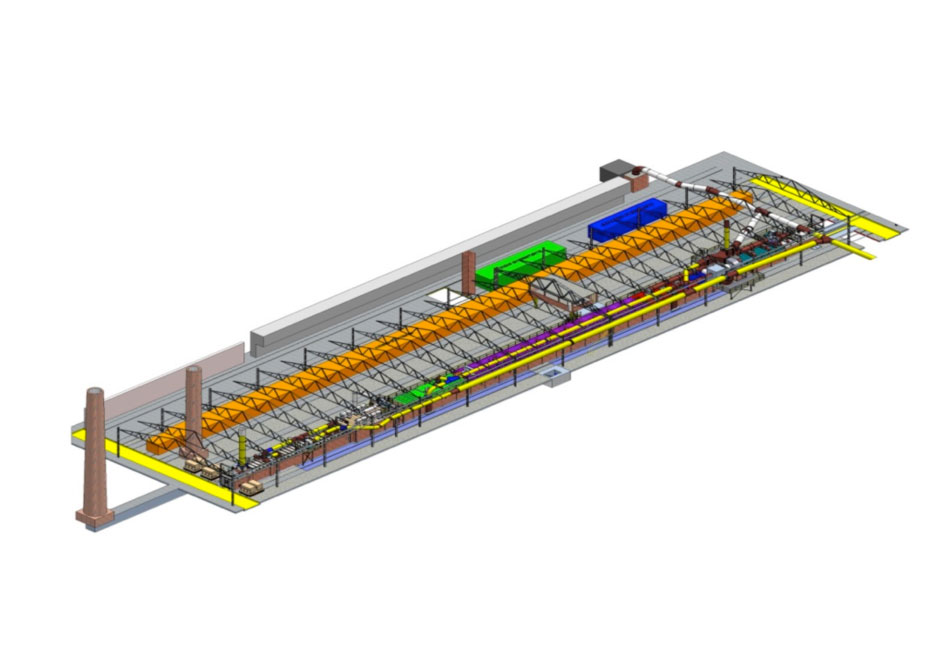

2011-Supplying the first entire production lines

Due to the supply of entire automation lines, 2011 was the year in which Beralmar supplied the first three production lines exclusively composed with our own equipment.

2010-Milestones in the equipment supply

This was the year when we had to deal with two remarkable situations.

On the one hand, Beralmar had manufactured and supplied its 500th heating generator (operating on fuel oil or solid fuels). This kind of technology had been manufactured since 1965.

On the other hand, Beralmar had supplied its 200th solid fuel burning installation for tunnel kilns. This was a remarkable figure that consolidated the company's global leadership in the field of solid fuel firing tunnel kilns. Beralmar has been offering these solutions since 1983.

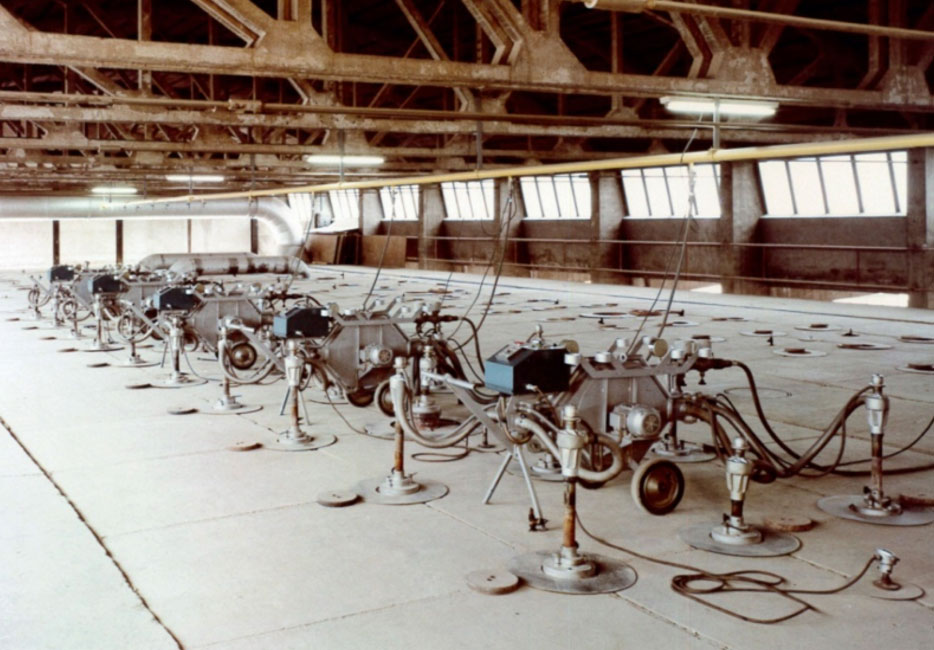

2009-Construction of a shuttle kiln used as a testing lab for gas burning equipment

A shuttle kiln was built to provide our R&D Department with laboratory equipment to conduct tests and trials. In this manner, we could acquire exact knowledge about our burner performance, in order to verify the specific characteristics and flame qualities of the new prototypes. Simultaneously, we could perform quality tests on all the manufactured burners before their delivery, by recreating similar conditions of where they were to be finally installed.

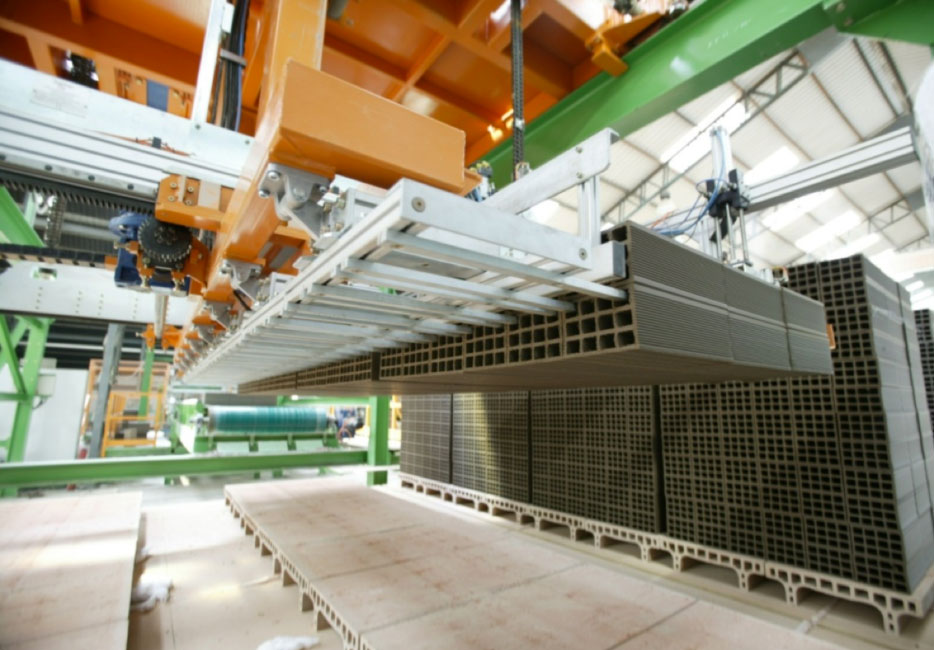

2009-Launching of the Automation Department

After several years, while contemplating on the possibility of having our own automation line, Beralmar took the opportunity to gather the most experienced professional team in this field in Spain. This way we were able to utilise first class technology. The new Department commenced with a significant workload.

2006-The construction of eight tunnel kilns begins

BERALMAR started the year by building eight tunnel kilns. Two of these projects were for entire plants.

Our technological experience allowed us to offer the broadest range of dryers on the market, depending on the characteristics of the clay and the kind of ceramic materials being produced. The offer of dryers included direct stacking on the kiln bogie, fast, with chambers and semi-continuous with shelves or platforms.

2005-R&D Department continues to be innovative

The R&D Department continued to develop its own products.

This was the year of the creation of the new FOC/20 range of cold flame gas burners. These burners can be installed between the preheating area and the draft fan.

Their installation harmonises the firing curve and anticipates preheating for a faster firing process. As a result, productivity had increased for kilns that were theoretically already working at their maximum capacity.

This same year, the self-igniting kiln burners were developed.

2004-Beralmar consolidates as an engineering company

Beralmar consolidated itself as an engineering company in several markets. This year we achieved our 25th engineering project for entire factories, kilns and dryers.

2003-Technological Innovation Prize

BERALMAR TECNOLOGIC was awarded the 2003 Chamber of Commerce Prize for Technological Innovation for “the development of a new combustion system using biogas obtained from urban waste”. The prize was received at a ceremony with more than 600 people in attendance and presided by the President of the Catalonian Government, the Right Honourable Jordi Pujol.

This year, the expansion of the plant that had begun in 2002 was completed. This expansion consisted in doubling the manufacturing and office facilities. In total, we have devoted 4,200 m2 to industrial units, 1,065 m2 to offices, and more space for yards.

Also this year, we delivered the first Micromatic micronised coal facilities. This has meant a significant step in the right direction for the utilisation of solid fuel combustion in the ceramic industry. This new system, along with the Promatic system, quickly expanded all over the world, with the delivery of more than 250 installations in 26 countries, in 2014.

2002-New name, new image

The 1st January 2002 BERALMAR began a new phase of its development.

After 36 years, QUEMADORES BERALMAR S.A. changed its name to BERALMAR TECNOLOGIC S.A. and released its new corporate image.

There was no intention to erase the origin of the company along with the disappearance of the name, QUEMADORES BERALMAR S.A. Quite the opposite, we continued to ensure that we were the best burner manufacturer, while at the same time, the objective was to include a broader scope of activities with the provision of engineering projects.

This was the year in which we built the first PRESTHERMIC hermetic tunnel kiln.

2001-Export Achievement Award

BERALMAR won the Chamber of Commerce exportation award for the second time, due to the strong and continuous growth in exports , with 50% of the Company's production being exported.

1998-The First Projects

Soon after, the first projects commenced, due to new customer support and confidence in Beralmar’s new phase of operations.

At the end of December 1998, Cerámicas Valera, S.A. from Santa Cruz de Mudela (Ciudad Real), commissioned a FORNTHERMIC kiln and a JETDRYER rapid drying room for a production of 300 metric tonnes per day for one metre assembled ceramics and roof tiles. This entirely new factory was commissioned in 1999.

In March 1999, Beralmar was entrusted by Briqueterie El-Rym de Annaba (Algeria) for the development of an entire factory for the production of 400 metric tonnes per day of bricks, with a

FORNTHERMIC kiln and a GARBÍ semi-continuous dryer.

During the first quarter of 2000, three new projects were delivered:

One MESTRAL semi-continuous dryer for Cerámicas Espíritu Santo in Alameda de la Sagra (Toledo) for the production of 650 metric tonnes per day of bricks and different thermal clay tiles.

On MESTRAL chamber dryer, a pre-kiln and the tunnel kiln extension for Cerámicas Borja de Alicante for the production of 55,000 roof tiles per day.

One tunnel kiln and one dryer for the Novaceramic plant located in Mexico for the production of 500 metric tonnes per day.

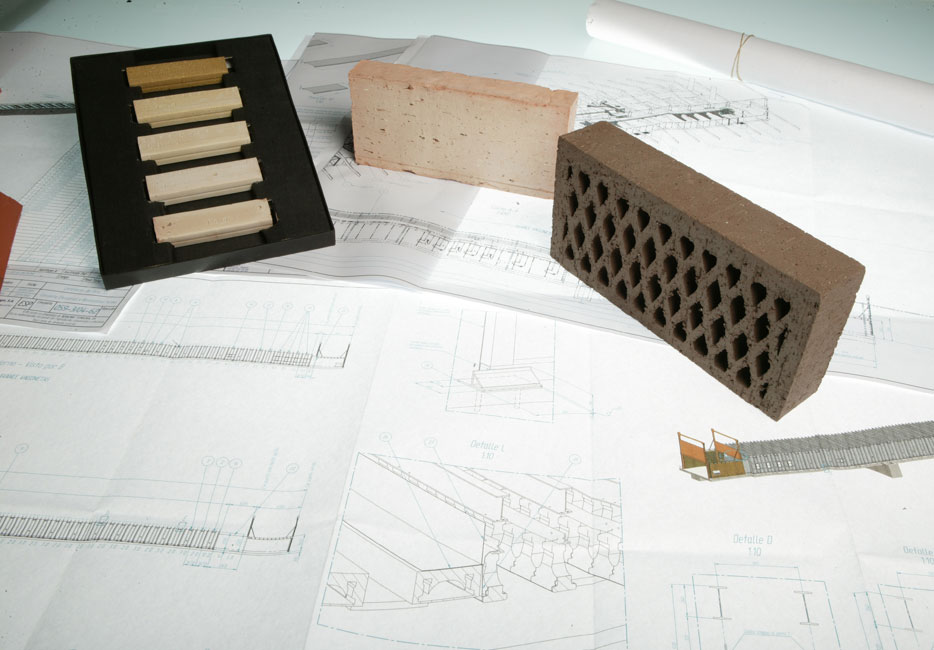

1996-New phase: kilns, dryers and entire plants

This new phase began back in January 1996, with the creation of a Project Engineering Department for the production of kilns, dryers and entire plants.

There were two main reasons for implementing this new stage:

- The first was based on market opportunities. It was identified that the markets where Beralmar was doing business, and also new markets under evaluation, had a growing demand for kilns, dryers and entire plants.

- The second was that the company had the operational knowledge and understanding of the ceramic processes and manufactured the capital goods. The next step was to offer the entire process.

1993-Manufacturing the first solid fuels installation, Promatic model

With this firing installation, the efficient and clean burning of solid fuels (mainly mineral coal and petroleum coke) was achieved.

From then on, other solutions were developed, such as the Micromatic model, which recognised Beralmar as a leader in this field.

1993 Export Achievement Award

The Terrassa Chamber for Commerce and Industry, which includes one of the most industrialised areas of Catalonia, honoured Beralmar with the Export Achievement Award. Exports amounted to 33% of the company's turnover. During this period, the results of a sound strategy were being reaped and the international outlook strengthened.

1990-Relocation to Terrassa

In 1990, the company moved from its Bòbila Almirall facilities to the newly created Els Bellots Industrial Park, the current location of Beralmar headquarters.

At the beginning, it consisted of an industrial unit and a 2,000 m2 administrative building.

1989-Manufacture of the first control equipment for a tunnel kiln

In the late 1980s CONTROL activity began with the development of MICROBER and MICROSEC automatic regulation and control equipment for tunnel kilns and dryers. It was a positive development, because this meant any existing tunnel kiln and dryer could be automated and the existing fuel systems could be enhanced. Moreover, it allowed the firing and drying process to be understood, which in turn deepened the specialisation of the company.

From then on, Beralmar was able to offer enhancement services for ovens and dryers and to perform appropriate retrofits to increase productivity. It was not only about providing the right solution for burners, but also about achieving overall improvements.

Starting to export

It was a strategic decision, which years later would become the main activity for the continuation and the growth of the company. Many resources and great efforts had been allocated for this purpose. Firstly for the closer markets, like Portugal and Morocco, and, then naturally, South America.

1982-Appointment of new CEOs

During the fuel crisis, there were significant changes in Beralmar: Cristóbal Caparros and Ramón Sarió were chosen as the Company's CEOs. The company Talleres Alpa was incorporated into the Beralmar organisation and the head office was relocated to Avenida Àngel Sallent No. 59, in Terrassa, attached to Bòbila Almirall.

In the early 1980s, and due to the economic difficulties, other fuels reappeared: coal and biomass. Burners were manufactured for working in an effective and modern way. The market addressed the situation by creating new machines, like the GQS/82 Burner and a range of CSD Combustion Chambers. This allowed a diversification of the agriculture sector based on the drying of agricultural products.

1976-Creation of the first natural gas burner for firing bricks

Markets evolved and Beralmar understood how to adapt to a changing environment. A new fuel appeared in Spain symbolising this progress: natural gas. As a result, the first gas burners used in Spain were being produced.

1964-Beralmar's foundation

Beralmar was founded in 1964 with the head office located at Sant Cugat del Vallès, at a brick factory called Almar. The production process was conducted at the company Talleres Alpa, in Terrassa, located in Bòbila Almirall. The company was established among kilns, dryers, clay and extruders... between bricks.

Its initial activity was the manufacture of the first fuel oil burner used in the Spanish structural ceramic industry. Afterwards, a hot air Generator for the dryer process was manufactured.

FIRING and DRYING were part of the company's main purpose.